Updating existing infrastructure can pose some significant challenges, especially when adding new pipework to storage tanks – achieving a perfect seal and retaining the wall strength are crucial to a successful project. When a Tier 1 contractor was updating a digester tank for a water utility, BC Civils was called in to install two reinforced sealing ‘plugs’ to complete the addition of new pipework in the tank.

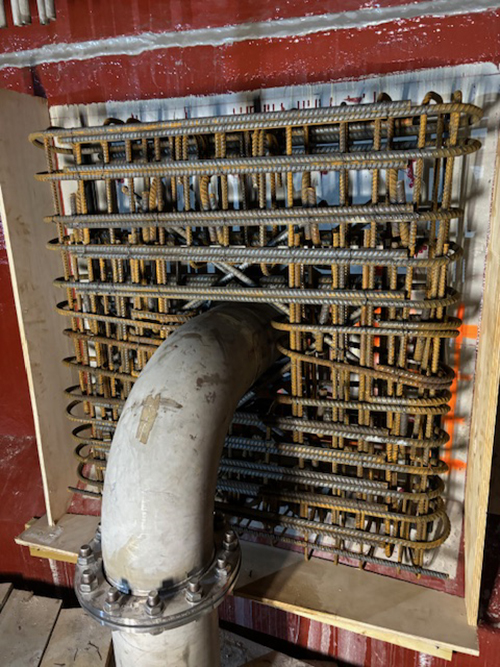

The anaerobic digester tanks are designed to hold thousands of gallons of digestate and manufactured from reinforced concrete. Two 400 mm diameter holes had been created to allow the new pipework to be installed and the next stage was to seal the holes and reinstate sufficient strength to the tank walls as the same time.

Installing two-tonne plugs

There were several challenges in this project, not least the position of the pipes, which prevented any supporting structure being propped from the floor of the tank. The water utility had provided an engineering drawing for the reinforcement that would be required inside the concrete plug, which would weigh around two tonnes when complete.

The first step was to drill 24 holes in the original tank wall around the pipe work to enable reinforcing bars to be fixed in place using specialist, high-strength resin. These were the basis for the additional reinforcing steel that would be encased in the concrete.

BC Civils also needed to create a temporary support structure that could hold the wooden shuttering in place while the concrete was poured. This involved fixing threaded rods into the tank walls and using them to secure the steel beams that held the formwork in place.

Restricted access

The only access to the interior of the tank was via a small hatch, which only added to the challenge of getting all the materials into position. This applied to the concrete as well, which was specified as a wet mix with a small aggregate size to allow it to flow easily around the pipework and reinforcing bars. The mix was installed using a concrete pump with a vibrating poker to eliminate air bubbles and ensure the required strength was achieved.

Adam Hickling, Operations Manager at BC Civils, commented: “Once the concrete had cured, we removed the formwork and temporary fixings before the site was cleared and the tank was handed back to the operator. Thanks to our experience of working to the high standards required by water utilities and their framework contractors, we are able to deliver projects of all sizes effectively and on time.”